OUR SERVICES

We provide services for the design and development of the future property, production of house kits to start construction. After that, Balkan Sip Company's team of builders goes to the site to provide the third type of services. This is the assembly of the house kit on the finished foundation and the erection of the construction project. The finished project is considered complete when it is ready for power supply, interior renovation and exterior cladding.

The first service ordered under the contract by the client is called ‘Design’. This stage is necessarily agreed with the customer and is carried out exactly according to his preferences. In essence, the project is the authorisation to build an environmentally friendly object (house, cottage, commercial or industrial building). Making a plan provides for a smart layout and improved facilities for the occupants.

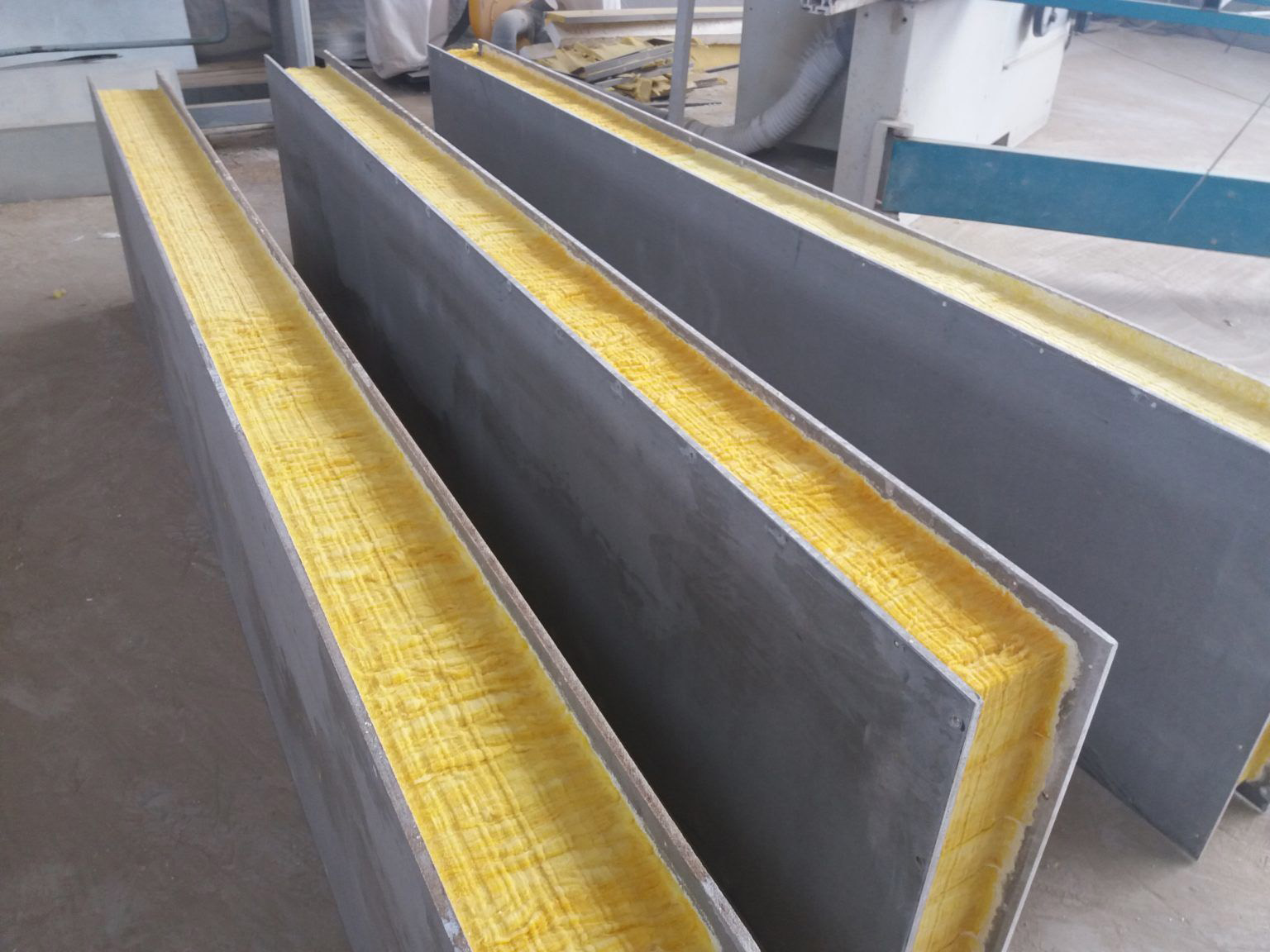

All kits are manufactured using structurally insulated panels (SIP) from floor to ceiling. The second service is to manufacture the kit based on the planned design and allocated budget. Ecological panels are cut at the factory using special equipment. SIP building kit is a pre-cut set of sandwich panels, which includes everything you need to build the foundation of your building. All the parts are precise and perfect, like pieces of a jigsaw puzzle.

The last stage is the assembly of the house set. The panels are installed directly on the foundation using fasteners and glue, and it is possible to assemble the structure on any type of foundation. At the final stage, the object is handed over to the client

Innovative and technological

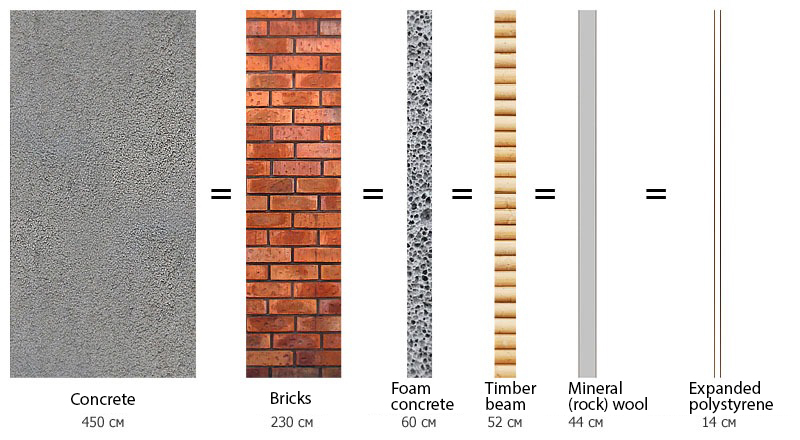

Structurally Insulated Panel (SIP) is a durable, modern building material consisting of two enclosing boards and insulation between them.

BALKAN SIP COMPANY LTD uses magnesite board from the world's leading manufacturers as the envelope.

Multifunctional magnesite board is a very durable, non-combustible, moisture-resistant and environmentally friendly material. It is based on magnesium chloride and oxide. Reacting, they form a particularly strong substance with a cubic crystal lattice, the so-called Sorel cement, which significantly exceeds the strength characteristics of Portland cement. A combination of materials is used as filler:

Fumed perlite, which is used in construction as thermal and acoustic insulation, in its composition resembling volcanic sand;

Wood sawdust of small fractions - gives magnesite sheet additional plasticity;

To increase strength, each side of magnesite board is reinforced with a layer of non-woven cotton material and basalt fibre glass mesh.

The main advantages of magnesite plate are:

✓ Increased moisture resistance.

✓ Ease and simplicity of installation.

✓ Absolute resistance to rotting.

✓ Fire resistance.

✓ Low thermal conductivity.

✓ High strength.

✓ Frost resistance.

✓ Anti-corrosion.

✓ Environmentally friendly.

✓ Resistance to biological processes.

Consumer properties of magnesite boards:

1.Fire resistance: Does not burn, does not emit smoke in open flames

2.Moisture resistance: Does not deform, does not soften, does not rot under the influence of moisture, vapour dampness.

3.Lightness: It has a density of 0.88-1.07g/cm3, easy to install.

4. Durability: It has anti-shock properties, low rates of deformation, under the influence of moisture, heat, dryness. Durable in operation

5. Sound insulation: with a thickness of 6 mm is 29 dB

6. Thermal insulation: the coefficient is 0.216W/m2

7. Frost resistance : More than 70 cycles. Retains its properties down to -40°C. Can be used to equip freezers. Dimensional stability

8. Environmentally friendly : Does not contain asbestos, formaldehyde and other harmful substances. Safe for people and animals

9. Antisepticity: Unlike chipboard and wood-fibre materials, magnesite boards have pronounced antiseptic properties and prevent the formation of fungus, mould and are not subject to destruction by insects. A great advantage of magnesite boards is the convenience and ease of processing, which does not require special tools and equipment.